Atex Regulations

It is of utmost importance to ensure safety and compliance with ATEX regulations when dealing with tire, plastic, cosmetics, and food applications. The handling of ATEX-rated materials must be carefully planned and executed to ensure safety and compliance. Here are some factors that can cause certain ingredients to be explosive:

High Chemical Reactivity

Explosive materials often contain chemical compounds with high reactivity. These compounds may have unstable chemical bonds that can rapidly break down, releasing a large amount of energy in the process.

Rapid Combustion or Decomposition

Explosive ingredients typically undergo rapid combustion or decomposition when ignited or detonated. This rapid release of energy creates an explosion.

Particle Size and Surface Area

Finely divided or powdered materials generally have a higher surface area, which can accelerate combustion by facilitating greater contact between the fuel and oxygen. This increased surface area promotes more rapid heat transfer and reaction kinetics, leading to faster combustion rates.

Oxygen-Rich Compounds

Many explosive compounds contain a high proportion of oxygen atoms in their molecular structure. Oxygen is necessary for combustion, and oxygen-rich compounds can release a significant amount of energy when they react with a fuel source.

Chemical Instability

Some explosive materials are inherently chemically unstable, meaning they can spontaneously decompose or react under certain conditions. This instability contributes to their explosive properties.

Temperature Range

Different materials have different temperature ranges at which they can combust. Some materials ignite easily at relatively low temperatures (e.g., paper), while others require higher temperatures to initiate combustion (e.g., metals). The autoignition temperature is the minimum temperature at which a material ignites without an external ignition source.

Presence of Flammable Gases or Vapors

Some materials release flammable gases or vapors when heated, which can ignite and sustain combustion. Examples include volatile organic compounds (VOCs) in paints, solvents, and fuels.

Our cutting-edge technology is designed and manufactured in strict accordance with Atex regulations.This means that our technology is safe, reliable, and meets all the requirements for operations in potentially explosive atmospheres as below described:

1- Risk Assessment

Conduct a thorough risk assessment to identify potential hazards associated with handling explosive materials. This should include considerations such as material properties, handling processes, environmental factors, and regulatory requirements.

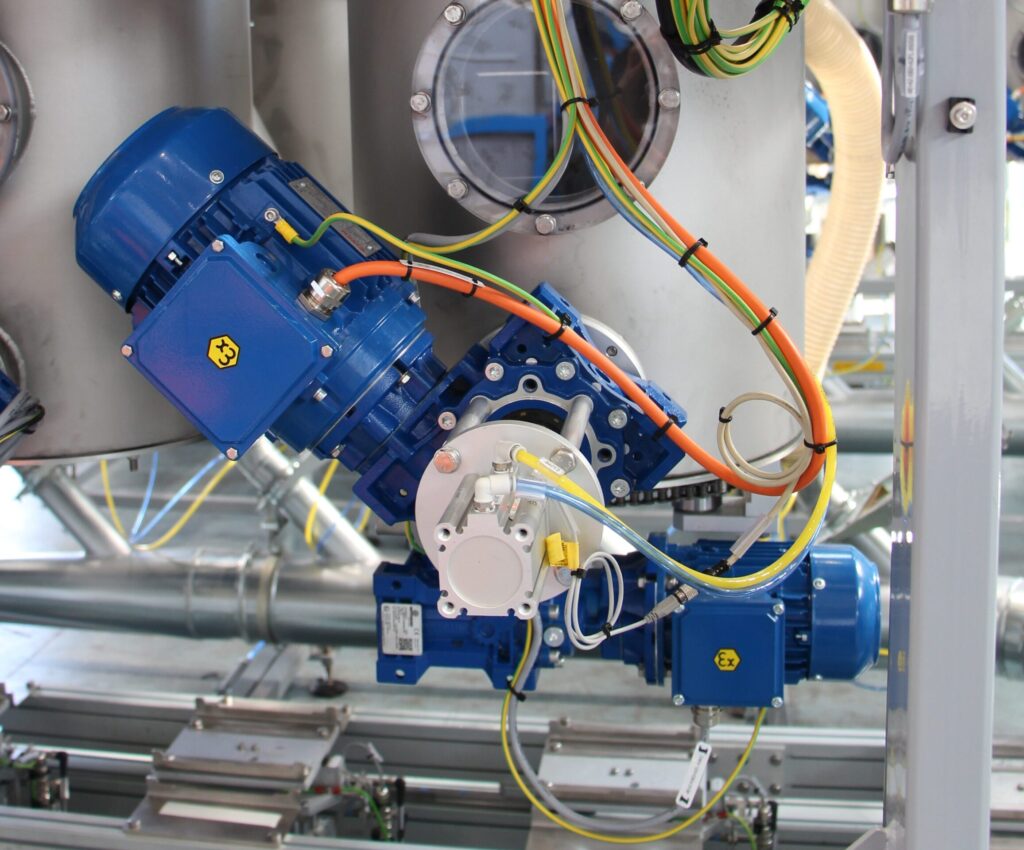

2- ATEX Compliance

Ensure that all equipment and components meet ATEX (ATmosphères EXplosibles) directives for hazardous environments. This includes selecting ATEX-certified motors, dosing screws, and other components that are specifically designed for use in explosive atmospheres.

3- Material Compatibility

Choose materials that are compatible with the explosive materials being handled. This may include materials that are resistant to corrosion, abrasion, and chemical reactions.

4- Grounding and Static Control

Implement proper grounding and static control measures to prevent static electricity buildup, which can ignite explosive materials. This may involve using conductive materials, grounding straps, and static dissipative components.

5- Control Systems

Implement control systems that allow for precise control of speed, dosing, and other parameters. This may involve the use of variable frequency drives (VFDs), PLCs (Programmable Logic Controllers), and other advanced control technologies.

6- Partner Selection

Choose a partner with expertise in designing and manufacturing equipment for handling explosive materials.

7- Testing and Validation

Perform testing and validation to ensure that the equipment meets performance requirements and complies with regulatory standards. This may involve prototype testing, field trials, and certification by third-party agencies.

By following these steps and working with the right partners, you can design and configure equipment that safely handles explosive materials in any industry.