Printing with liquid dyes

Precision in preparation

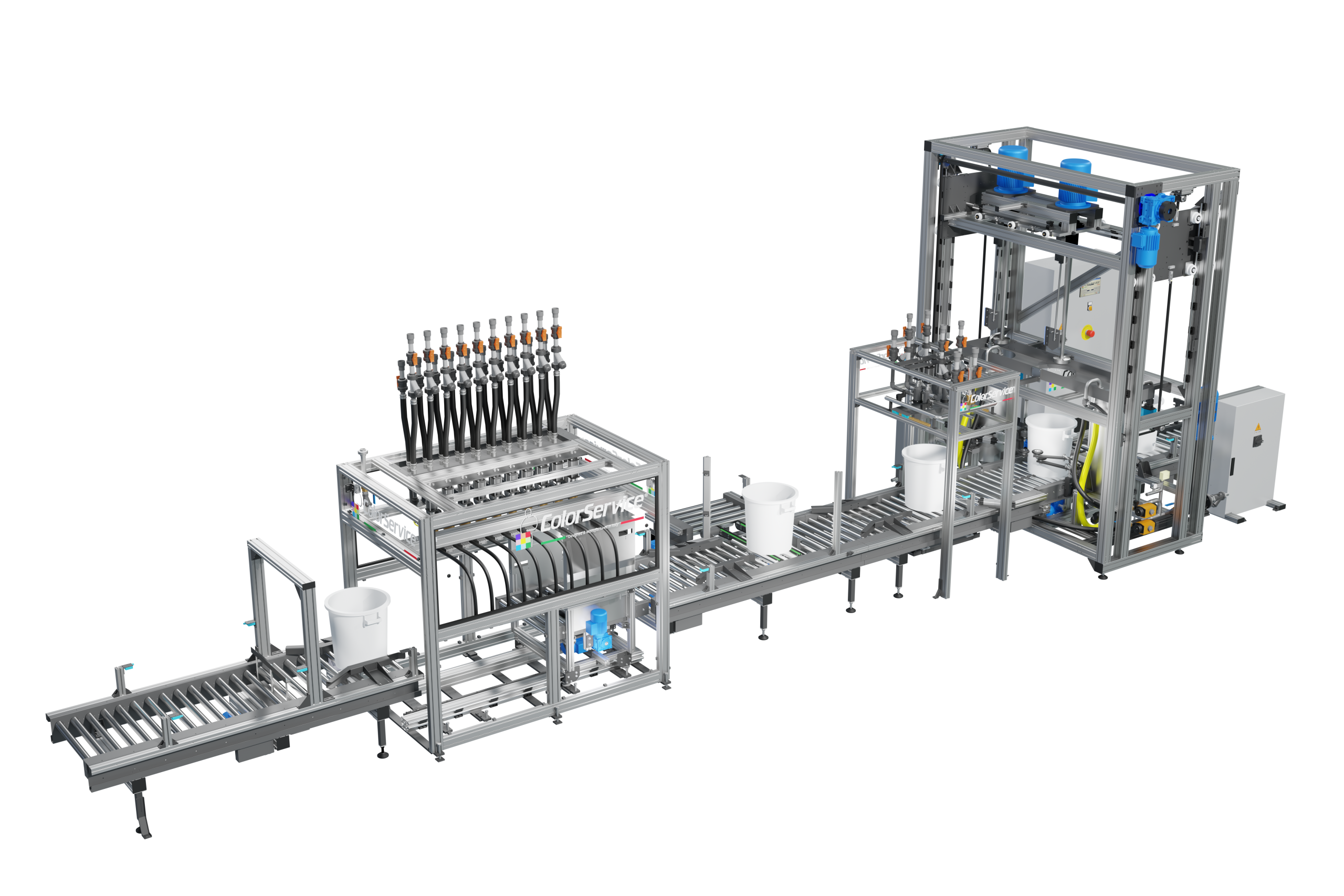

Printing automation brings high precision with proportional valves. Same valve brings fast flow or accurate slow drops. All for final precision.

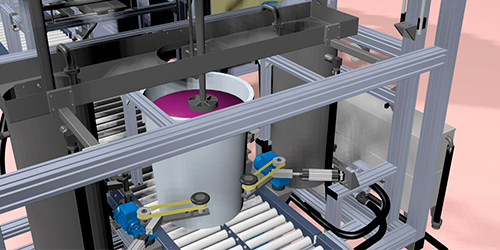

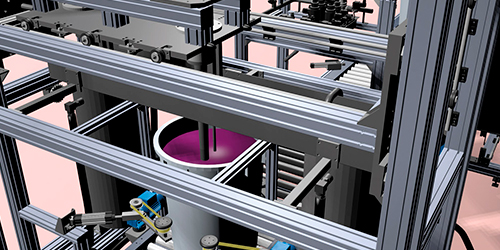

High performance stirrer

Mixing of printing paste is very important. That is the reason Color Service has a perfect-engineered stirrer to deliver homogenous printing paste. You never need to use filter anymore.

Sandwich type preparation

In order to improve mixing performance, Color Service prepares dyes between mother paste layers. Mixing result is always perfect.

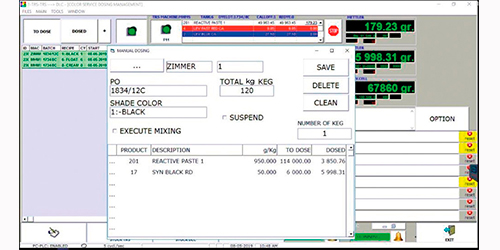

Perfect reproducibility

It is not matter for Color Service to 30 kg to 120 kg, every amount can be exactly the same. No need to prepare more for safety margin. If printing paste is not enough, Color Service repeats the same exact colour again without fail.

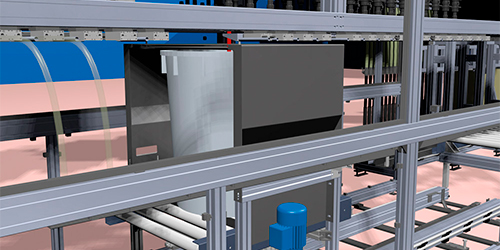

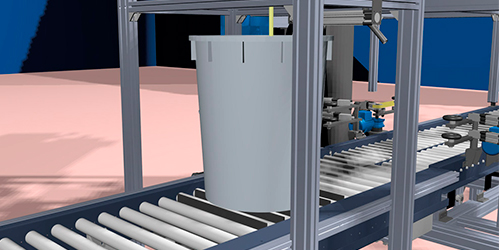

Only single operator for all process

Printing automation is fully automatic. All units are connected with roller conveyors integrated with motors and sensors. No any human operation is required.

Dye recycle

The intelligent software allows to operator to recycle of dyes. The additional parts of mother paste or dyes are calculated in automatic to transform the other shade of colours.

Rotate of drum during mixing

In order to guarantee homogenous mixing, stirrer moves up and down as well as turns the drum.

Powerful software

The calculation of each recipe is done and stored by Color Service printing recipe management.