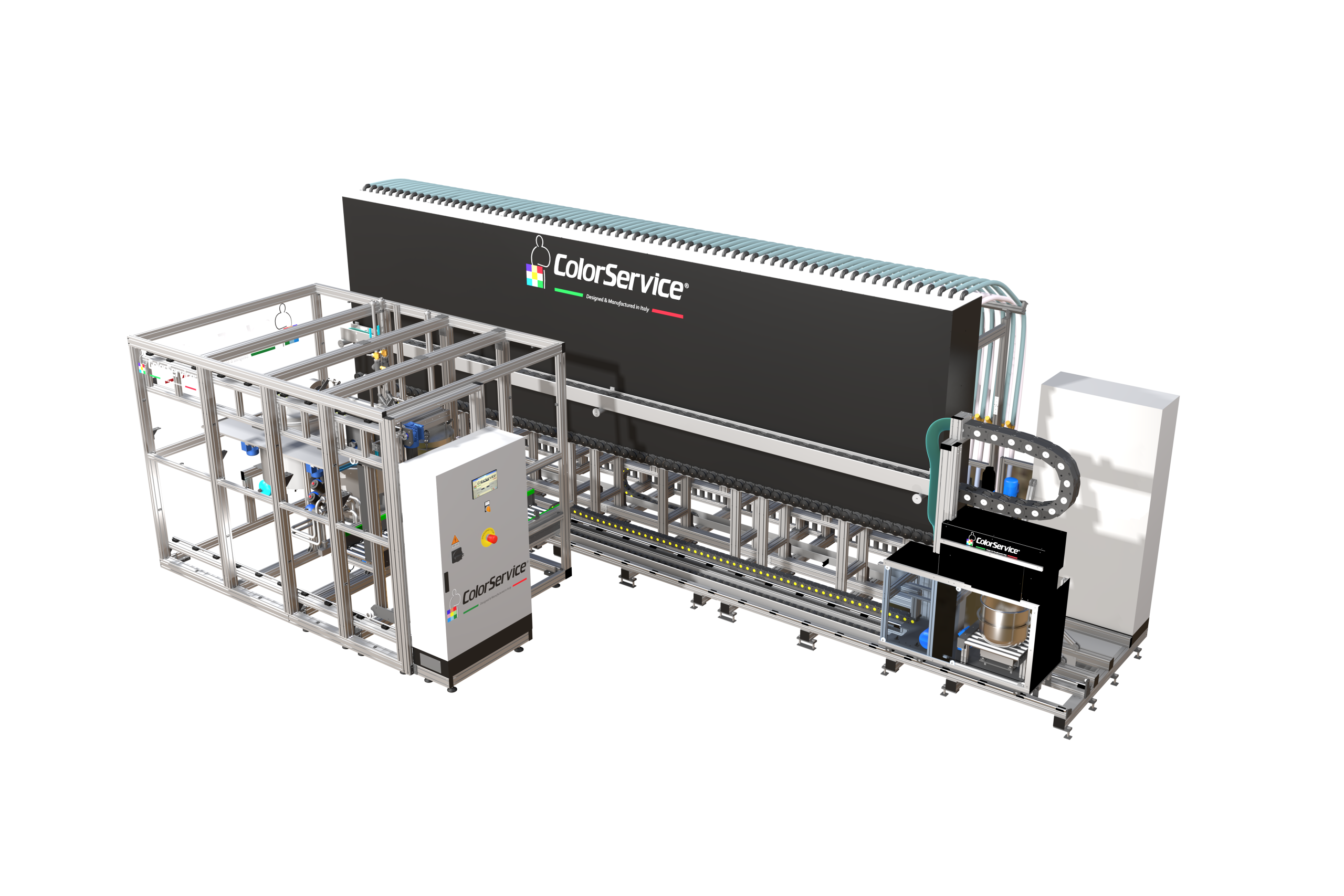

Automation for powders TRS

Stainless steel silos for long lifetime

Thanks to stainless steel silos, many advantages can be achieved. In addition to allowing a long life, stainless steel guarantees maximum hygiene and cleanliness and eliminates static electricity which causes stick products in silos and it gives strong construction to blow down easily ingredients in case of “powder bridge” inside of silo. Air blow from top of the silo eliminates stuck of products and pushes them down easily.

Best precision

TRS represents the most accurate weighing system in the market. It is not scale accuracy, real weighing accuracy is done by TRS as 0.01 gram of powder. Thanks to patented scraper, the particles flow down very fine and TRS can control perfect accuracy.

Windproof trolley

Weighing trolley of TRS is windproof. After bucket moves inside of trolley, it is closed and sealed to protect against wind and not let powder flies away.

No worry of powders out of automation

If some non-frequent powders are not in automation, nothing to worry about it. TRS moves trolley to the side of machine and let operator to add them manually. The rest of operation is still full automatic.

Modular silos

Block of silos can be chosen from 90 litre to 450 litre according to powder consumption. Even it is possible to add in the future or replace with new capacities.

Vacuum loading

Loading powders is a simple and safe process. Each silo is equipped with an independent filter, loading pipe, and valve. The vacuum process starts by using a barcode reader or control panel to identify the type of material.

Self-Cleaning filters

Filters are cleaned using reverse air blow instead of vibration, thanks to the silo technology. Other materials create creaks, but stainless steel is safe and long-lasting.