The Most Frequently Asked Questions About Our Dosing Systems

In industries where accuracy, safety, and material handling are critical to performance, our systems distinguish themselves through adaptability, reliability, and engineering excellence.

Below, we address some of the most common questions we receive about how our technology manages complex materials, ensures compliance with international standards, and integrates seamlessly into diverse production environments.

Material Behaviour

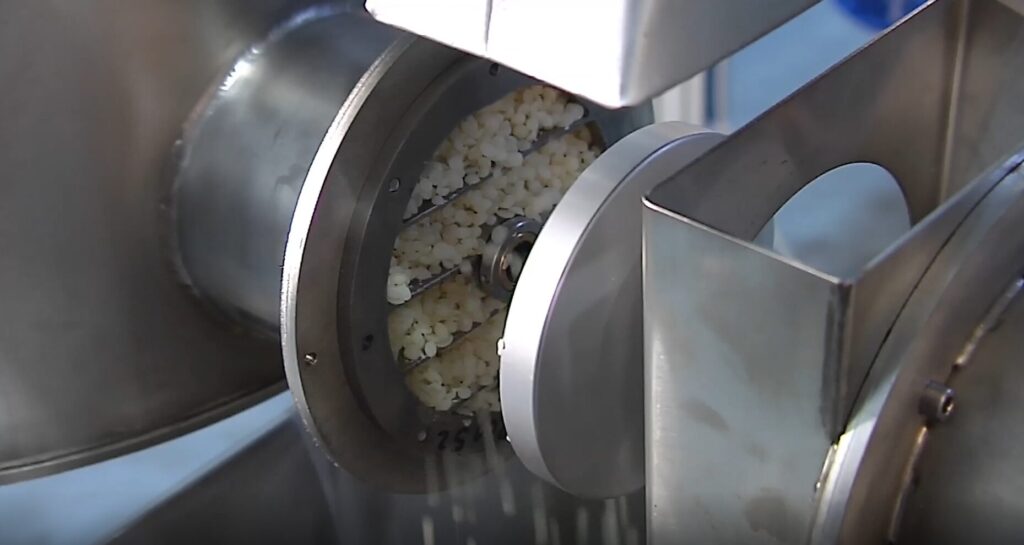

Material behavior can vary significantly and, to address the challenges, we have developed a range of advanced design features, including:

- Heated Lines for Liquids: Maintain liquids at the ideal temperature to prevent solidification or viscosity changes, especially for heat-sensitive substances like resins and polymers.

- Conditioned Systems for Powders: Control humidity, temperature, and pressure to prevent agglomeration and ensure uniform flow, reducing compaction and cohesion issues.

- Level Sensors: Monitor and adjust material levels in real-time to avoid overloading or shortages, ensuring consistent and precise dosing with automatic flow regulation.

- Custom Screws for Weight and Product Form: Screws are tailored for precise weight dosing or adjusted based on product shape and density, ensuring optimal flow for different materials.

Every solution is custom-engineered to suit the properties of the client’s specific ingredients.

Certified to the Highest Standards

Compliance is built into every system from day one. Our solutions are developed in accordance with ISO, CE, ATEX, and FDA hygiene requirements, depending on the intended application. This ensures every installation meets the regulatory expectations of your industry, whether it’s food processing, chemical manufacturing, or advanced materials production.

By integrating compliance considerations from the earliest design stages, we enable our clients to streamline validation processes, reduce audit complexity, and maintain absolute confidence in the safety, quality, and reliability of their operations.

Versatility Across Ingredients and Applications

Every production environment is different, and so are the materials you work with. Our systems are designed to handle a broad spectrum of ingredients, including:

- Powders (from fine micro-ingredients to dense minerals);

- Liquids (from volatile solvents to viscous oils);

- Pastes and resins (including high-viscosity and temperature-sensitive compounds);

- Acids and reactive chemicals, with full corrosion-resistant configurations.

Each setup is tailored to your material properties, ensuring optimal accuracy, stability, and ease of operation. This versatility means you can rely on one system to manage multiple ingredient types without compromising performance.

Seamless Integration Into Your Production Line

Modern production environments rely on connectivity, and our systems are built to fit right in. Whether your facility runs on SCADA, PLC, or MES systems, our technology is fully modular and integration-ready.

That means:

- Easier communication with your existing control architecture

- Centralized monitoring and reporting

- Improved traceability and production efficiency

With this flexibility, it is possible to expand the system capabilities, scaling smoothly as the production grows.