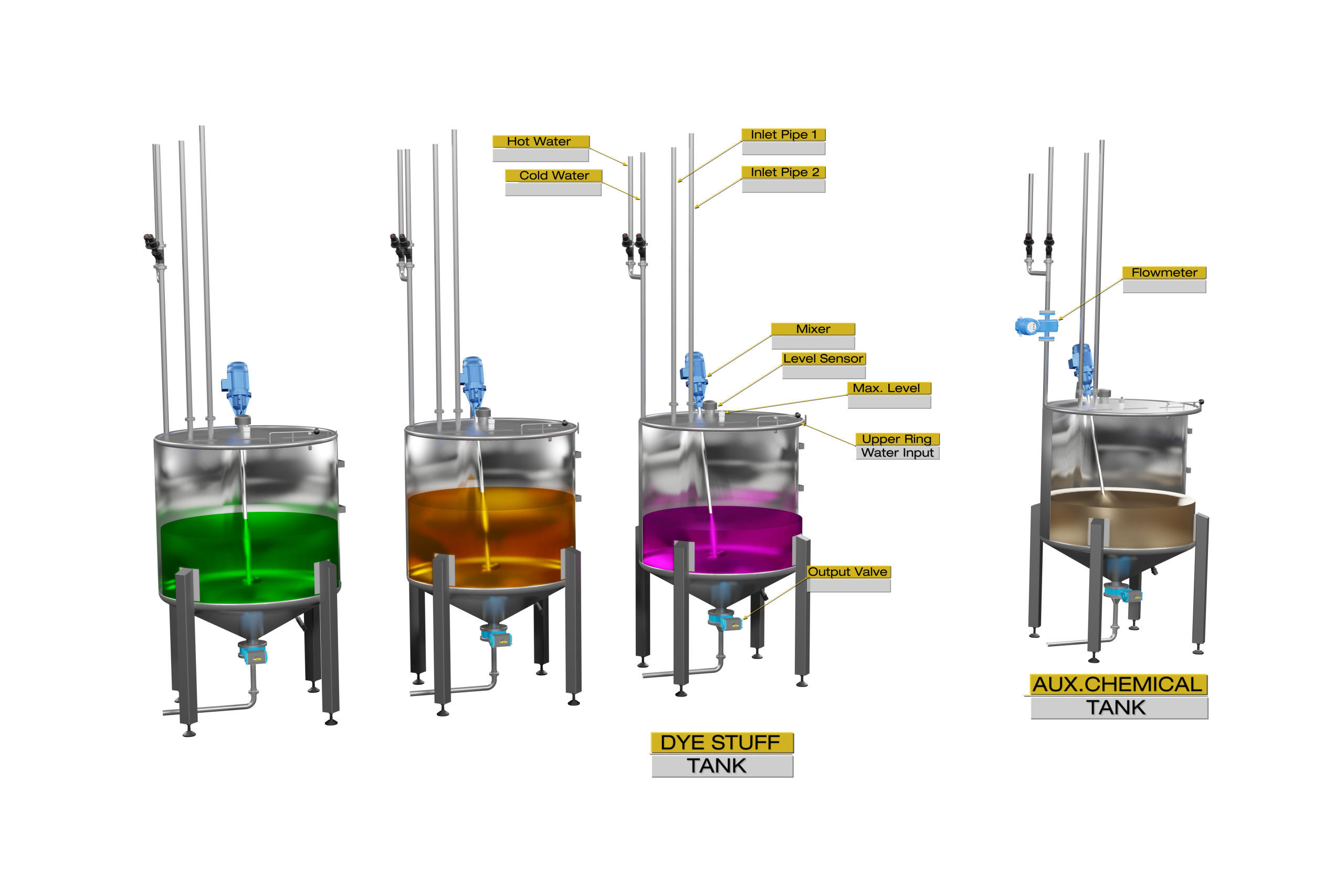

Continuous process Water make-up

Continuous process

Color Service dispersers are suitable also for continuous process. Required amount of dyes, liquid or powder chemicals are sent to service tank for continuous machines precisely with some water. Remaining water is added into top of chemicals locally. Batch is made homogenous before to use by continuous machine. Color Service controls water inlets, stirrer of tank as well as feeding to continuous machines.

Repeat same batch, no problem

Same batch can be repeated many times but consistency is a big problem. However, Color Service repeats same concentration for small or big amount of batches. It is not required to prepare all amount in one step, it is possible to split according to tank capacity. Color Service repeats same concentration.

Automatic repetition

Field panels of each continuous machine control level of service tank and create the request to dispenser to prepare another portion. This process goes on until arrives to total scheduled amount of batch; without any human intervention. If more than one tank is assigned to continuous machine, clever control system of filed panels switch from one tank to other to give you smooth operation.

More precision for dyes

In order to increase precision of dye bath, Color Service provides analogic level sensors working with radar technology. Water quantity is calculated as volume very easy.

Not enough to send dyes or chemicals only

Due to nature of continuous process, it is necessary to top up by water to required batch amount. Thanks to local field panels of Color Service, adding water is done under control. This guarantees exact amount as well as exact concentration of bath.