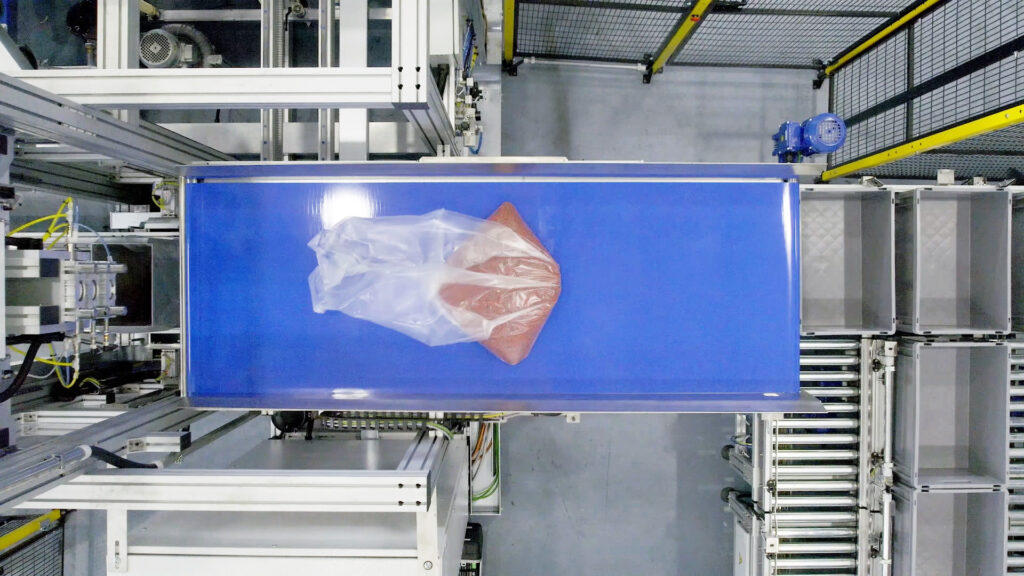

Advanced Ingredient Weighing and Bag Creation System

Our innovative ingredient weighing system represents a cutting-edge, fully automated solution for dosing and packaging needs. Seamlessly integrated with an automatic bag creation system, it streamlines the processes of weighing, sealing, and sending to the Banbury, drastically reducing production time and improving operational efficiency. Every stage of the process is precisely monitored, ensuring a high-quality end result.

Key Features of the System

- Precise Ingredient Weighing: The system ensures highly accurate weighing of ingredients, meeting the required specifications for each dosage.

- Automated Bag Creation: The packaging process is entirely automated, with bags created and sealed directly during the weighing phase. Manual intervention is no longer necessary, reducing the risk of errors and increasing productivity.

- Bag Sealing and Identification: Each bag is securely sealed to prevent leaks and then identified with a TTO (Thermal Transfer Overprinter), ensuring complete traceability of the product throughout the supply chain.

- Final Weight Control: During the sealing process, the system conducts a precise weight check to ensure the contents meet specifications. In case of discrepancies, the bag can be rejected or corrected, maintaining the highest quality standards.

- Various Bag Sizes: The system is designed to work with bags of different sizes, easily adapting to the specific needs of each customer or product type.

- High-Quality Materials: Bags can be made from materials such as EVA or PE, which offer excellent performance in terms of resistance and protection. These materials are ideal for a wide range of industrial applications, from food to chemical industries, ensuring optimal protection of the contents.

- Versatility in Applications: The system is suitable for a broad range of sectors, including food, pharmaceutical, chemical, and cosmetic industries. Its flexibility allows it to be tailored to the specific needs of each client, offering a customized solution for every application.

Thanks to this state-of-the-art technology, our system not only enhances operational efficiency but also reduces costs associated with manual errors and downtime. With a fully automated process, productivity increases significantly, enabling businesses to meet growing market demands more quickly and precisely.

Discover how our advanced weighing and packaging system can optimize your production line, ensuring superior quality and improving the management of your industrial processes. With our technology, the future of your production is already within reach.